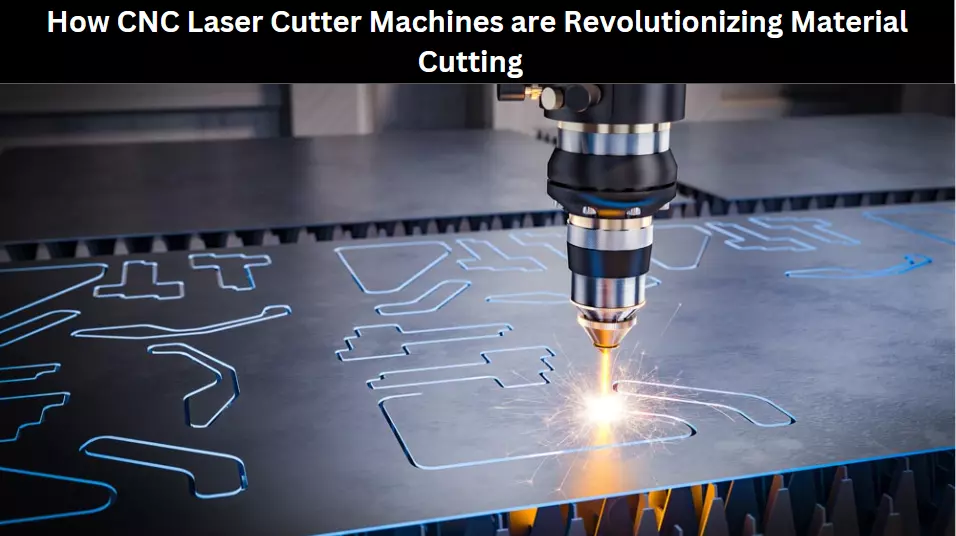

CNC laser cutter machines have emerged as powerful tools in the manufacturing industry, revolutionizing the way materials are cut. With their unmatched precision and efficiency, these machines have become integral to a wide range of applications, from industrial manufacturing to artistic creations. In this article, we will explore how CNC laser cutter machines have transformed material-cutting processes, enabling intricate designs, reducing waste, and improving overall productivity. We will delve into the key features and advancements that contribute to their precision and efficiency, ultimately reshaping the landscape of material cutting.

The Evolution of CNC Laser Cutter Machines

CNC laser cutter machines have come a long way since their inception. Initially used primarily for industrial applications, they have now become accessible and affordable for small businesses, artists, and hobbyists. Technological advancements have led to the development of more compact and user-friendly machines, making them versatile tools for various industries. The integration of sophisticated software and control systems has enhanced their capabilities, allowing for precise and efficient material cutting.

Unparalleled Precision in Material Cutting

One of the key advantages of CNC laser cutter machines is their exceptional precision. Unlike traditional cutting methods, laser cutters provide unparalleled accuracy, enabling the creation of intricate and complex designs. The focused laser beam emits intense heat, effectively vaporizing or melting the material, resulting in precise cuts with minimal heat-affected zones. This precision is particularly beneficial for industries such as aerospace, where intricate parts and components require exact specifications.

Efficiency and Speed in Material Cutting

CNC laser cutter machines are renowned for their efficiency and speed. These machines can swiftly process various materials, including metals, plastics, and wood, allowing for faster production rates. Laser cutters excel in their ability to quickly and accurately cut complex shapes and patterns, significantly reducing production time compared to traditional methods. Additionally, the integration of automation and advanced software enables continuous operation, minimizing downtime and maximizing productivity.

Reducing Waste and Enhancing Cost-Effectiveness:

CNC laser cutter machines contribute to a more sustainable approach to material cutting by significantly reducing waste. The precision of laser cutting minimizes material loss, as the narrow laser beam produces narrow kerfs, resulting in optimized material usage. Furthermore, the ability to nest designs efficiently maximizes the use of available space, reducing scrap and material waste. This not only benefits the environment but also enhances cost-effectiveness for businesses, as they can save on raw material costs.

Expanding Design Possibilities

CNC laser cutter machines have opened up a world of design possibilities. Their precision and versatility enable the cutting of intricate patterns, curves, and detailed designs that would be challenging or impossible with other cutting methods. Whether in industrial manufacturing, architectural models, or artistic creations, laser cutters provide the freedom to explore innovative and imaginative designs, empowering individuals and businesses to bring their ideas to life.

Conclusion

CNC laser cutter machines have truly revolutionized material cutting with their precision, efficiency, and versatility. The advancements in technology have made these machines indispensable tools across various industries, from large-scale manufacturing to individual artistic endeavors. Here you can see a lot of CNC machines that can make you advance in your industry As technology continues to advance, we can expect further enhancements in precision and efficiency, paving the way for even more innovative applications in the future.