In the intricate dance of commerce, packaging plays a pivotal role that goes far beyond mere containment. It is a critical component in product preservation, an influential tool in marketing, and a key element in distribution efficiency. The choice of packaging materials can significantly impact a product’s shelf life, appeal to consumers, and even its transportation costs. In this article, we explore the various types of packaging materials used across different industries, delving into how each material contributes to the overall functionality and aesthetics of packaging.

Overview of Common Packaging Materials

Plastics

Plastics stand as the most adaptable and prevalently utilized materials in the packaging industry. This category encompasses a variety of subtypes, each exhibiting distinct characteristics to serve diverse packaging requirements. PET (Polyethylene Terephthalate), recognized for its clarity, strength, and lightweight nature, is widely chosen for beverage bottles and food containers. PVC (Polyvinyl Chloride) is lauded for its durability, making it a go-to choice for medical packaging and cling films. LDPE (Low-Density Polyethylene) is celebrated for its flexibility and moisture resistance, ideal for crafting plastic bags and flexible lids.

An additional facet of plastic’s versatility is evident in flexible packaging solutions, which include materials like polyethylene films used in wraps and pouches. These options provide lightweight, adaptable, and often resealable choices, particularly advantageous in the food and consumer goods sectors. You can find out more about what kind of packaging this is in the article “How Is Flexible Packaging Made“.

While plastics have brought about a revolution in packaging due to their versatility, they also confront environmental concerns, primarily stemming from their non-biodegradable nature, which necessitates careful consideration and management.

Paper and Cardboard

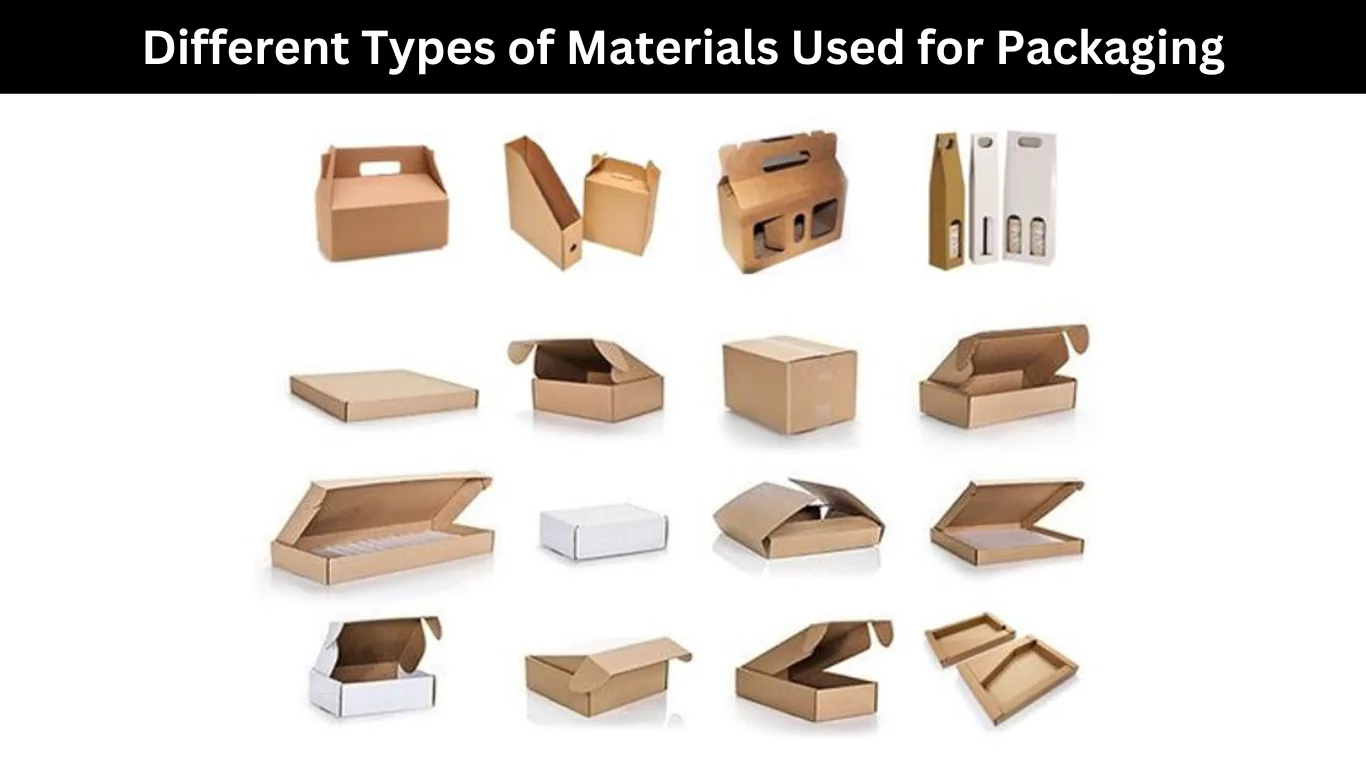

Paper and cardboard are the stalwarts of pack materials, offering an eco-friendlier alternative to plastics. Corrugated cardboard, characterized by its fluted inner layer, provides excellent protection and is extensively used in shipping boxes. Kraft paper, known for its strength and durability despite its lightweight, is widely used in grocery bags and wrapping materials. These materials are not only recyclable but also biodegradable, making them increasingly popular in response to growing environmental concerns.

Metals

In the realm of packaging, metals like aluminum and tinplate offer distinct advantages. Aluminum is lightweight, corrosion-resistant, and provides an excellent barrier against air and light. It’s widely used in beverage cans, foil wrappings, and aerosol containers. Tinplate, typically steel coated with a thin layer of tin, combines the strength of steel with the corrosion resistance of tin. This makes it an excellent choice for food cans, where product preservation is paramount.

Glass

Glass is a time-honored material in packaging, revered for its purity and sustainability. Its non-porous surface doesn’t react with the contents, making it ideal for food and beverage packaging, as well as pharmaceuticals. Glass can be recycled indefinitely without loss of quality, adding to its environmental appeal. However, its weight and fragility are considerations that sometimes limit its use.

Emerging and Innovative Packaging Materials

As the packaging industry evolves, innovative materials are being developed to meet the growing demand for sustainability and functionality. These advancements are reshaping the way products are packaged.

Bioplastics

A significant development in the realm of different pack materials is the emergence of bioplastics. Unlike conventional plastics derived from petroleum, bioplastics are made from renewable resources like corn starch, sugarcane, and cellulose. Types of bioplastics include PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates), both known for their biodegradability. The environmental benefits of bioplastics are significant, as they reduce dependency on fossil fuels and offer lower carbon footprints. They are increasingly used in applications ranging from disposable cutlery to flexible film packaging.

Edible Packaging Materials

Edible packaging is a groundbreaking innovation, offering an environmentally friendly solution to packaging waste. Made from natural and edible ingredients like seaweed, starch, and even chocolate, these materials can be consumed along with the product they encase. In the food industry, edible packaging has potential uses in coating, wrapping, and containing foods, potentially reducing the need for traditional packaging materials.

Advanced Composites

Advanced composite materials are being developed for enhanced protection in packaging. These composites often combine polymers with other materials like fibers or nanoparticles to create packaging with superior strength, barrier properties, and durability. Such materials are particularly beneficial in scenarios where extreme protection is needed, such as in the transportation of fragile or high-value items.

Packaging Materials for Specific Applications

Food and Beverage Industry

In the food and beverage industry, packaging materials must ensure food safety and preserve the quality and freshness of the product. Materials like PET, glass, and certain bioplastics are commonly used due to their non-reactive nature and ability to maintain the integrity of the contents. Innovations like oxygen-scavenging and moisture-resistant materials are enhancing the shelf life of food products.

Pharmaceutical Industry

The pharmaceutical industry requires packaging materials that guarantee sterility and safety. Materials used must prevent contamination and maintain the efficacy of the pharmaceutical products. Blister packs, made from a combination of plastic and aluminum, are widely used for their protective properties. Additionally, advanced materials that provide tamper evidence and child resistance are increasingly important in this sector.

Electronics and Consumer Goods

Packaging for electronics and consumer goods focuses on protection, especially from physical damage and electrostatic discharge. Materials such as antistatic bubble wrap, conductive foam, and rigid plastics are commonly used. These materials not only protect the product from impacts but also prevent damage from static electricity, which is crucial for sensitive electronic components.

Sustainability and Environmental Considerations

In an era increasingly defined by environmental consciousness, the impact of different types of materials used for packaging on the planet cannot be overstated. Traditional materials like plastics, while versatile and cost-effective, often pose significant environmental challenges due to their non-biodegradable nature and contribution to ocean pollution. Conversely, materials like glass and metals, though recyclable, require significant energy for production and recycling processes.

The packaging industry is actively responding with efforts to enhance recyclability and sustainability. Bioplastics and recycled materials are gaining traction as alternatives to traditional plastics. Companies are also embracing strategies like lightweighting, where less material is used without compromising packaging integrity, and designing for recyclability, ensuring that the end-of-life disposal of packaging materials is environmentally friendly.

Global Trends and Future Developments

Global trends are profoundly influencing the choice of packaging materials. The rising awareness of environmental issues is pushing consumers and companies towards sustainable packaging options. This shift is prompting innovations in material science, leading to the development of new, eco-friendly packaging materials.

Future developments in packaging materials are likely to be driven by technology and sustainability. We can anticipate greater use of advanced biodegradable materials, such as enhanced bioplastics, and the incorporation of smart technologies in packaging for improved recycling and waste management. The integration of digital features like QR codes and AR may also become more prevalent, offering enhanced user experiences while minimizing physical packaging needs.

Conclusion

The selection of the right packaging materials is a critical decision that affects not only the product’s success but also its environmental footprint. Understanding the different types of materials used for packaging is essential for businesses to balance functionality, environmental impact, and consumer demand. As the packaging industry continues to evolve, the focus will likely remain on developing materials that are not just effective in protecting and presenting products, but also aligned with the global imperative of sustainability. In this dynamic landscape, the future of packaging is poised to be innovative, responsible, and responsive to the evolving needs of both the market and the planet.