There exist various and common kitchen and factory-related injuries and cuts of varying severity, gravity, and intensity which are preventable with acquiring maximum protection. Such cuts and injuries are more common than burns in terms of being occurred frequently. These hazardous happenings aren’t surprising, particularly when people utilize several bladed instruments and applications to cook or prepare foods on daily basis. From blenders to knives to peelers, there is a large number of chances to accidentally mound and mutilate yourself when practicing the skills of preparing food for your family. Here comes the essentiality of cut resistant gloves along with purchasing full-arm protection gloves.

Protect yourself from cuts that are lesser in seriousness, importance, and significance

It’s sensible to safeguard your hands from slight and insignificant burns and cuts as you consider the protection from hazardous ones. Minor cuts are more likely to become severe if left untreated, not managing the required precautions. People don’t consider slight injuries as serious and critical ones, without realizing that any open wound of the arm or hand is more likely to have desperate complications, causing other disorders.

When intending to cut meat utilizing a wooden board, it’s rational to wear cut-proof gloves. This is essential since hands are used for everything people perform on daily basis so, protection from being a victim is crucial because this body area is exposed to multiple bacteria. Cut resistant gloves can safeguard not only from cuts and wounds but from hazardous bacteria either. A single cut on the finger or hand may result in being infection risk, particularly for persons who are suffering from long-term physical fitness issues or contain weaker immune systems. Such workers require additional precautions, wearing sturdy and long-lasting full arm protection gloves.

Key criteria

There exist numerous key criteria you might require to bear in mind before determining to purchase heat resistant gloves. For your assistance, consider the certain directions to the criteria by which marketers ranked and tested top and uppermost cut-resistant gloves. For instance, material, grade, and size matter in terms of a higher standard, functioning and safeguarding. The single most critical factor to consider before having the determination of purchasing heat and cut-resistant gloves is the stuff or material, entrepreneurs made gloves from. Material plays a crucial role when it comes to preventing injuries.

Different fibers and their significance

In most cases, you will notice cut resistant gloves manufactured and assembled of different fibers the combination of which facilitates workers to acquire maximum protection. Fiberglass, spandex, polyethylene, and nylon cause magnificent types of material, giving additional strength tofull arm protection gloves. Spandex and nylon give numerous properties in which elasticity is worth noticing. This combination provides the ability to the resuming of glove’s normal shape after being stretched. Further, essential durability and strength, which is significant either, come through nylon and spandex amalgamation. There is a range of different features that arrives through polyethylene including consolation, safety, and comfort. Since it is denoting substance, you might observe and notice it is lightweight, sturdy, and flexible.

Fiberglass and its characteristics

Fiberglas provide various advantages for employees working in industries but the most vital is abrasion-resistant property.

Moreover, it protects the body from the process of being eroded by water, wind, and other natural agents which cause various physical complications. If you require the most favorable and optimum protection against abrasions and cuts in factories, kitchens, or other indoor and outdoor chores it’s essential to prioritize the existence of fiberglass when manufacturers tend to incorporate sturdy and powerfully built material.

Coatings matter on the palms of gloves

It’s also a better concept to consider various kinds of coatings on the gloves’ palms. Effective and excellent polyurethane coatings enable you to have a sturdy grip on what you’re grasping.

So, the existence of this excellent feature speaks that you didn’t compromise a better purchase for heat or cut resistance. Without having a sturdy grip on the objects you tend to grasp, cut resistant gloves don’t worth the price.

Besides, you require observation and consciousness of the grading rolled and filed on the product detail for any pair of heat-resistant gloves.

Various grading systems

There exist different grading structures and orders for numerous types of resistance. So, it’s critical to ensure the buyer is conscious regarding which one is which. The most ordinary and usual resistance grading you will figure out, linked with full arm protection gloves, is the grading that relates to abrasion resistance. Scrapping and rubbing are among which occur frequently, that’s why people consider this property when intending to acquire cut resistant gloves. Abrasion resistance grades range from zero to five, with zero being the less than average whilst five being the greatest vertical extent. Consider having elevated in terms of grading when determining the purchasing process. Upraised and aerial ratings indicate that such particular gloves are worth noticing and deserve to be utilized for different chores.

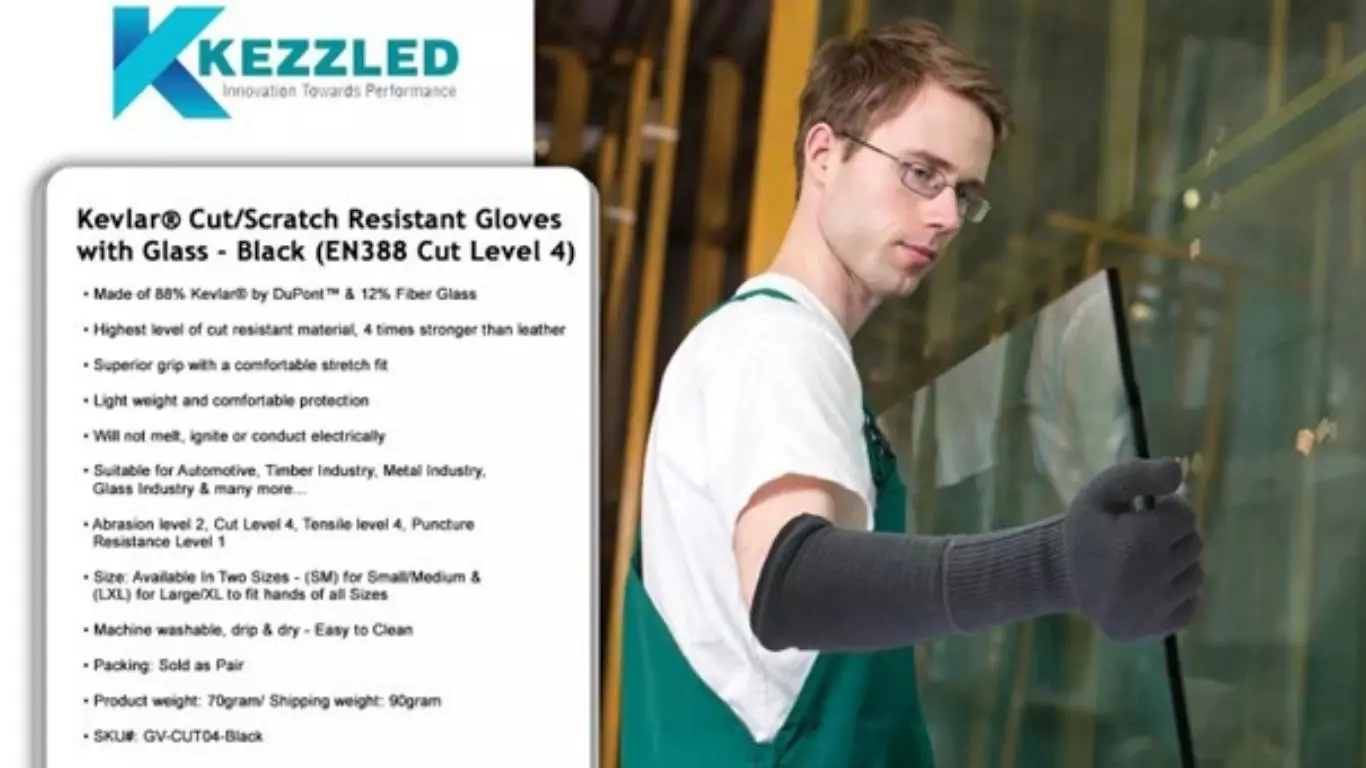

Gloves graded 5 are the only way to examine the standard, helping you acquire the best piece. Sturdy material matters in terms of consumers’ interest but grading is another magnificent factor to measure admiration and commerciality. The state of being favored by immeasurable consumers supports heat resistant gloves and indicates that they’re worth buying. Nevertheless, preventing cuts and abrasions is feasible through sturdy material of a different class only. Get Kevlar heat and cut resistant gloves from Kezzled now.